ABOVE: The majority of impacts arise from feed production, chicken meat processing and the grow-out phase for the birds.

The following was taken from the CSIRO research paper by MA Copley and SG Wiedemann from Integrity Ag and Environment and can be read in full at publish.csiro.au/an/pdf/AN22230

The environmental sustainability of industries and food products has become a key focus for consumers and governments worldwide.

Sustainability covers a broad range of topics – from the purely environmental to socio-economic issues.

This is reflected in how – though climate action is the most prominent sustainability issue – energy, water and land are also priorities in Australian life-cycle assessment of agri-food products.

LCAs of chicken meat have, in multiple regions of the world, found that it is a low-impact meat product.

For Australian production, Wiedemann et al. reported greenhouse-gas impacts that were similar or slightly lower than those for chicken meat overseas, with the majority of impacts arising from feed production, meat processing and the grow-out phase for the birds.

The study used data from 2008–2009 and covered two major supply chains but omitted some major production regions and was therefore incomplete as a baseline for the industry.

Shifts in production region, productivity and feed sources over the subsequent decade are expected to have changed the environmental footprint of chicken meat, and further insight is needed to understand change over time before considering potential reduction targets into the future.

In 2021, the Australian Government made a commitment to deliver net-zero economy-wide emissions by 2050.

The pathway, outlined in Australia’s Long-Term Emissions Reduction Plan, is technology-driven and aims to facilitate emissions reduction in all sectors of the economy by reducing the cost of existing and emerging technologies and accelerating their adoption.

Understanding the contribution of fossil energy to the environmental footprint of the Australian chicken meat industry, and how it compares with other sources of impact, is a first step in assessing how and to what extent the industry can rely on the LTERP and decarbonisation of electricity grids to reduce fossil energy consumption and GHG emissions.

A key challenge the industry faces is how to accelerate other viable emission reduction strategies and work with supply industries, such as the feed grains sector, to reduce impacts in the mid-term (2035) and long-term (2050).

A core principle of the LTERP is that the transition to a net zero economy should not put industries, regions or jobs in jeopardy.

Therefore, the chicken meat industry faces an imperative to balance its economic and environmental priorities while continuing to provide high-quality food.

In response to this, the industry is in the process of developing a sustainability framework to assess, report and track change in performance.

Critical to the success of the framework is the establishment of industry-wide benchmarks across a range of environmental categories, identification of factors contributing to these impacts, understanding past performance, and ongoing reporting to track performance over time.

While action on climate change is an imperative, assessing a broader suite of indicators is beneficial to bring a more holistic approach to improving performance, and to avoid unintended burden-shifting.

Water consumption, stress and availability are major issues in the Australian environment and counter-cyclical consumption and availability – that is where consumption is greatest when availability is lowest – can have far-reaching consequences.

Though the chicken meat industry is responsible for water consumption and stress impacts, it is also exposed to impacts arising outside its operation control in other industries, most notably via feed grains.

Similarly, land occupation is an environmental priority where, though the chicken meat industry has a direct contribution to land occupation and management, it is exposed to impacts arising from outside its operational boundary.

This study provides a contemporary baseline for the Australian chicken meat industry and focused on environmental impacts as one key area of sustainability.

This baseline is fundamental to the identification of major impact sources, the investigation of mitigation strategies and to supporting future improvement in industry performance in the face of emerging market and economy-wide priorities.

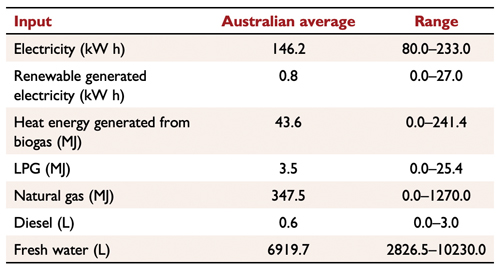

Table 5. Meat-processing inputs (n = 11) reported per 1000kg of carcass weight processed.

Goal and scope

The study was an attributional LCA of Australian chicken meat production from conventional and free-range housing systems.

All major production regions were assessed using primary industry data, representing nearly 50 percent of birds processed in Australia.

This study aimed to:

- Determine carbon footprint, freshwater consumption (water footprint) and water stress, fossil energy and land occupation impacts for Australian C and FR chicken meat production

- Assess impact hotspots in the supply chain

- Compare trends over the past decade.

This information will be used in subsequent work to determine impact reduction pathways for the Australian industry.

Main impact sources in the supply chain

For both C and FR systems, feed production was the major impact source across all environmental indicators.

Of this, cereals were the major contributor to all indicators, except for LU and dLUC, where soymeal was the major commodity driving emissions.

This study found that the average emission intensity of feed was 0.45kg CO2-e/kg (or 1.09 kg CO2-e/kg, including LU and dLUC), compared with 0.36–0.46kg CO2-e/kg – or 0.38–0.88kg CO2-e/kg, including LU and dLUC – adjusted to AR5 values.

The emission intensities of feed, excluding LU and dLUC, in a study of UK production were approximately twice (1.11, 1.03 and 0.91kg CO2-e/kg) that of this study, and feed production in that study, still the major emission source, represented slightly more of the total GHG impacts (70 percent).

A key driver behind the difference in emission intensity of feed (excluding LU and dLUC) between this study and the 2010 study was the increased N2O emissions from feed grain production identified over the past decade.

Brocket al., studying grain production in 2010, found that the emission intensity of wheat produced in central NSW was 0.2kg CO2-e/kg, whereas Simmons et al. reported the intensity as 0.315kg CO2-e/kg (both in AR4 values) for wheat from the same region, an increase of more than 50 percent reported eight years later.

This finding did not necessarily reflect the actual increases in emissions, rather a better insight into key emission factors and production systems, resulting in higher reportable emissions for cereal grain.

More generally, Simmons et al. reported the emission intensities of cereals produced in 14 regions, all of which were higher than that reported by Brock et al. in their single region case study.

This suggests that the reported emission intensity of Australian wheat is higher than was previously understood, resulting in an underestimate of impacts in previous studies.

At this time, the Australian feed grain sector is yet to release a strategy for emission reduction, meaning that there is no short-term indication on whether a change in the emission intensity of feed grains (and the emission intensity of meat chicken feed) can be expected.

The water and land footprints of chicken meat production were also highly exposed to upstream impacts from feed production.

As most land occupation was attributable to arable uses, the key variable influencing arable land use was crop yield, which was influenced by source region and use of irrigation.

Irrigation of grain resulted in a trade-off between water and land, which trended in different directions when comparing irrigated and non-irrigated grain – high irrigation led to high water consumption but lower arable-land occupation, and vice versa.

Accordingly, water consumption, stress-weighted water use in the supply chain and the emission intensity of feed exhibited considerable variation based on grain source regions.

Though differences in freshwater consumption and water stress are inherent, given general climatic differences among source regions, the environmental impacts of grain and, by extension, chicken meat are significantly affected by interannual climatic variability.

The freshwater consumption and water stress results also demonstrate the potential of inter-annual variability and the need for ongoing assessments to establish a clear trend and benchmark for environmental impacts.

A severe drought on Australia’s eastern seaboard, beginning in early 2017 – which saw rainfall levels at or below the previous record lows for a significant portion of NSW and southern Queensland – was made worse by record-high temperatures that increased the evaporation rate of what water was available.

The years 2017–2019 saw the record-lowest rainfall for NSW and the Murray Darling Basin – record-low rainfall was also recorded in parts of Victoria and Western Australia.

This had significant repercussions for the average freshwater consumption and water stress in each state’s grain market, which flowed through to the chicken meat industry.

Drought conditions meant that the proportion of irrigated grain available for feed on the eastern seaboard was substantially and anomalously over-represented in comparison to years where rainfall was closer to the average.

Water consumption in the NSW and Queensland average wheat markets of financial year 2018/19 and FY2019/20 for meat chicken feed was 114.5 and 80.3L/kg wheat respectively, water stress was 113.4 and 44.0L H2O-e/kg respectively.

This indicates that the regions in NSW from which wheat was sourced for meat chicken rations relied on higher levels of irrigation and water was considerably more scarce, to which the AWARE indicators (13.6 and 8.2sq m respectively) align.

In comparison, water associated with the average WA wheat market for meat chicken feed was 6.7L/kg wheat, with a WSI of 2.7L H2O-e/kg as the vast majority of WA wheat was grown in dryland conditions, even with the low rainfall recorded in southern WA.

Though domestically produced feed grains accounted for such a significant proportion of impacts, they were (except for water consumption and stress) of a relatively low impact compared with those of imported soybean meal.

Demand for this low-cost high-protein commodity was high, not only within the Australian chicken meat industry but also in the egg and pork industries.

With soybean meal being a major export commodity for South America, global demand has driven a rapid expansion and the conversion of pasture or forest to cropland, leading to substantial GHG emissions from dLUC.

As most imported soybean meal in the Australian feed market is now derived from South American production, compared with a decade ago where a greater volume came from the US, imported soybean meal has become a significantly higher impact feed commodity – especially in terms of LU and dLUC – driving the difference between the LU and dLUC results from this study and those of Wiedemann et al.

Utilising accredited soybean meal or alternative protein sources – for example canola meal, field pea, animal meals – as a partial or complete substitute for high-impact imported soybean meal would reduce LU and dLUC emissions.

However, trade-offs and challenges may emerge as a result of doing so.

Many growers drew a proportion of their energy requirements from renewable sources – almost exclusively solar – but this accounted for only a small portion of the total industry energy demand.

Aside from drinking water, the major consumptive use of water at the farm was for cooling.

Innovations or management changes in cooling, such as combined sprinkler and evaporative cooling pads may offer reductions in on-farm water consumption.

At the meat processing plant, average energy, water and GHG impacts declined slightly compared with the 2010 study, indicating improved plant efficiency.